Why Australia Must Embrace Industrial Automation Now

As the global manufacturing landscape continues to evolve at breakneck speed, Australia risks falling behind if it doesn’t take decisive steps to adopt industrial automation. While other countries race ahead with smart factories, robotics, and automated production lines, many Australian manufacturers are still relying on outdated, labour-heavy processes.

At Process Evolution, we design and build bespoke automated machines and advanced manufacturing lines tailored to Australian industries. We believe industrial automation is not just the future — it’s a necessity. This blog explains why now is the time for Australian manufacturers to act and how local expertise can drive global competitiveness.

The Global Shift Towards Industrial Automation

How Leading Nations Are Investing in Automation

Countries like Germany, Japan, South Korea, and China have made industrial automation central to their manufacturing strategies. Their factories are adopting robotic systems, smart sensors, and AI-driven workflows at scale — resulting in higher productivity, better quality control, and reduced costs.

According to the International Federation of Robotics, global robot installations are rising year-on-year, with Asia and Europe leading the charge. These regions recognise that automation is the key to future-proofing manufacturing.

Australia’s Automation Adoption Rate Lags Behind

In contrast, Australia has one of the lowest robot-to-worker ratios. Many businesses are hesitant to invest due to perceived complexity, upfront costs, or a lack of local expertise. This slow uptake puts our manufacturers at a strategic disadvantage.

Why Industrial Automation Is No Longer Optional

Labour Shortages and Rising Operating Costs

Skilled labour is becoming harder to find, particularly in regional areas. Rising wages, safety obligations, and high turnover rates are pushing operational costs up. Industrial automation helps alleviate these challenges by handling repetitive, dangerous, or precision tasks more reliably than manual labour — and often at lower cost over time.

The Need for Increased Productivity and Consistency

Australian manufacturers are under pressure to increase throughput without compromising quality. Automated machines ensure repeatable, high-precision processes that reduce defects, minimise waste, and improve lead times. Automation brings consistency and scalability.

Meeting Global Manufacturing Standards

Export markets expect a certain level of efficiency and quality. Embracing industrial automation is essential for Australian producers to meet global compliance standards and remain competitive. It’s not just about making things faster — it’s about producing to world-class standards reliably.

The Risk of Falling Behind Without Action

Lost Competitiveness in Key Australian Industries

Without investment in automation, local manufacturers may find themselves priced out by overseas competitors who produce faster, cheaper, and with fewer errors. This is especially relevant in commodity-driven sectors where margins are thin, and production efficiency is vital.

Missed Opportunities in Local and Global Markets

Australia has a reputation for high-quality manufacturing, but without the efficiencies offered by industrial automation, we risk being overlooked in favour of lower-cost or higher-output producers. Automation opens the door to new markets, including exports and high-volume contract manufacturing.

What Industrial Automation Really Looks Like Today

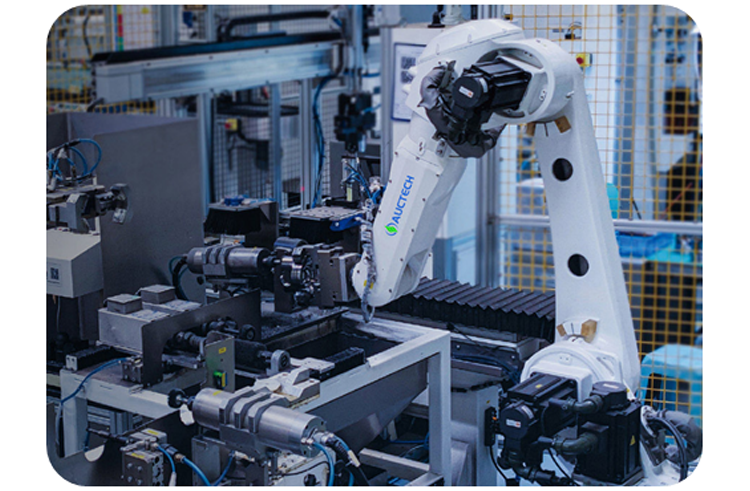

From Cobots to Custom Automated Machinery

Modern industrial automation is more flexible than ever. It’s no longer limited to high-speed car factories or massive plants. Cobots (collaborative robots), pick-and-place machines, automated conveyors, and integrated smart systems can be implemented in businesses of all sizes.

At Process Evolution, we build:

• Robotic packaging and palletising cells

• Flexible capping machines

• Automated assembly systems

• Pail filling lines

• Special-purpose machines tailored to your product

Why Local Solutions Matter More Than Ever

The Value of Australian-Engineered Systems

Automation is not one-size-fits-all. Australian manufacturers face unique conditions — including limited factory space, batch production models, and seasonal labour. That’s why locally engineered solutions are critical. Off-the-shelf systems often fail to deliver real-world results in our environment.

Local Support, Faster Turnaround, Better Results

Working with a local provider like Process Evolution ensures:

• Faster response times for service and support

• Access to spare parts without long overseas delays

• Customisation based on real factory layouts and needs

• Better communication and ongoing collaboration

Tailored Automation for Unique Australian Needs

We specialise in bespoke automation — not cookie-cutter systems. Whether you need a one-off machine or a complete production line, we’ll design, build, install, and support it right here in Australia. Our team works with you from concept to commissioning, with a focus on long-term results.

How Process Evolution Supports Australian Manufacturers

Bespoke Automated Machines Built Locally

We engineer and manufacture automation solutions from the ground up — purpose-built for your product, your process, and your space. Every machine is tailored, tested, and supported locally.

Turnkey Manufacturing Lines Backed by Experience

With over 25 years of experience in advanced manufacturing and automation, our team has solved some of the industry’s most complex production challenges. We deliver:

• Detailed concept layouts and simulations

• End-to-end integration

• R&D support for novel applications

• Full commissioning and training

Real Partnerships, Real Results

We see ourselves as long-term partners — not just equipment suppliers. Our goal is to help Australian manufacturers thrive by applying world-class automation practices with local knowledge and craftsmanship.

It’s Time for Australia to Step Up

Getting Started with Industrial Automation

You don’t need to automate everything at once. Many manufacturers start small — automating a single task or bottleneck — then scale over time. Our team can help identify high-impact areas, provide concept visuals, and deliver practical automation roadmaps to match your budget.

Why Waiting Is the Biggest Risk of All

Every year of delay costs time, money, and opportunity. Competitors who invest now will widen the gap in cost-efficiency and delivery speed. The longer you wait, the harder it becomes to catch up. Industrial automation is no longer a “nice to have” — it’s a strategic priority.