Robotic Case Packing: Flexible and Scalable Automation

Why Robotic Case Packing Is the Future of End-of-Line Automation

The Shift from Manual to Robotic Case Packing

Manufacturers across Australia are under increasing pressure to deliver more with fewer resources. Manual packing once dominated end-of-line operations, but as product diversity and labour costs have grown, traditional processes have struggled to keep pace.

Robotic Case Packing offers a smarter, faster, and safer solution. By automating case erecting, loading, and sealing, manufacturers can dramatically improve consistency and throughput while reducing their reliance on manual labour.

The Need for Flexibility in Multi-SKU Operations

Today’s production lines rarely run a single product. Frequent changeovers between bottle sizes, closure types, or packaging formats are now the norm. This complexity demands flexibility — and that’s where robotic systems excel.

Modern robotic case packers can automatically adjust to handle multiple SKUs without lengthy setup or mechanical changes, making them ideal for contract manufacturers or brands managing a wide product portfolio.

How Automation Addresses Labour and Productivity Challenges

Labour shortages continue to affect manufacturing nationwide. Automating end-of-line processes helps Australian companies stay productive and competitive by reducing dependency on manual labour, minimising workplace injuries, and ensuring output consistency — even in multi-shift environments.

What Is Robotic Case Packing?

The Core Principles of Automated Case Erecting and Packing

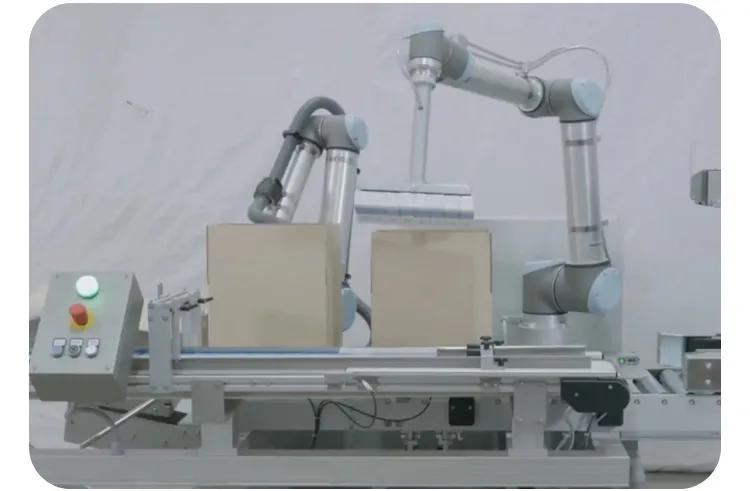

Robotic Case Packing involves using robotic arms or gantry systems to automatically form, fill, and seal corrugated cases. The process typically includes:

1. Case erecting – forming flat blanks into cartons or trays.

2. Product collation and loading – grouping products and placing them into cases.

3. Case sealing and discharge – closing, taping, or gluing cartons before moving them downstream.

Each step is synchronised for maximum efficiency, ensuring every case is packed precisely and ready for palletising.

How Robots Handle Varied Product Types and Packaging Formats

Robotic systems are designed to manage bottles, jars, tubs, pouches, sachets, and cartons. They use vision systems, custom grippers, and programmable logic to adapt instantly to each format — without manual intervention.

Top-Load, Side-Load, and Custom Robotic Configurations

Different production lines require different loading orientations.

• Top-load packers place products vertically into cases and are perfect for bottles, jars, and tubs.

• Side-load systems push or slide products horizontally, ideal for cartons or pouches.

• Custom configurations can be engineered for unique applications, combining both orientations or integrating with other robotic functions such as labelling or palletising.

The Benefits of Robotic Case Packing Systems

Consistent Quality and Reduced Downtime

Robots don’t tire or vary in performance, delivering perfectly aligned, consistently sealed cases every time. Automated fault detection and error-proofing minimise rework and downtime, keeping production running smoothly.

Increased Throughput and Adaptability

Robotic systems can operate continuously across multiple shifts, significantly boosting daily output. When product specifications change, quick-adjust tooling and pre-programmed recipes make the transition fast and straightforward.

Safer and More Ergonomic Work Environments

Automating repetitive case-packing tasks reduces manual lifting, bending, and twisting. This not only protects workers but also creates a safer, more sustainable workplace with fewer injuries and improved morale.

Flexible Automation for Multi-SKU Packaging Lines

Recipe-Based Programming and Rapid Changeovers

Flexibility is at the heart of modern Robotic Case Packing. With recipe-based programming, operators can switch from one product to another in seconds using an intuitive touch-screen interface. Every recipe stores parameters such as case dimensions, pack counts, and stacking patterns — eliminating lengthy manual adjustments.

Handling Different Product Sizes, Shapes, and Pack Counts

From small bottles to large cartons, robotic case packers easily adapt to diverse product ranges. The combination of servo-driven actuators, smart sensors, and modular grippers ensures gentle handling and perfect placement regardless of product size or material.

Integration with Case Erectors, Conveyors, and Palletisers

When combined with automated case erecting and palletising, robotic case packers create a seamless, end-to-end packaging workflow. Process Evolution’s systems integrate effortlessly with upstream fillers and downstream palletisers to deliver a fully connected, high-efficiency packaging line.

Scalable Robotic Solutions That Grow with Your Business

Modular Design for Expanding Production Capacity

Every Process Evolution system is built with scalability in mind. Start with a single cell today and expand later with additional modules — whether it’s dual-line operation, additional grippers, or integrated vision systems.

Future-Proofing Through Software and Hardware Upgrades

Because robotic systems are software-driven, upgrades can extend their lifespan and capability. Our engineers can update control logic, add new motion sequences, or integrate sensors as your production evolves.

Connecting Robotic Case Packing with Smart Factory Systems

Integration with Industry 4.0 platforms allows live production monitoring and data-driven decision-making. Robotic systems can track performance, uptime, and output in real time — supporting predictive maintenance and continuous improvement.

Why Choose an Australian Partner for Robotic Case Packing

Designed, Built, and Supported Locally

At Process Evolution, we design, build, and support all our Robotic Case Packing systems right here in Australia. Local manufacturing ensures that every system is tailored to meet Australian production standards and environmental conditions.

Faster Installation and On-Site Service Response

Working with a local automation partner means quicker lead times, faster commissioning, and immediate support. Our engineering team provides on-site training, service, and troubleshooting to keep your production running without delays.

Compliance with Australian Safety and Quality Standards

All Process Evolution systems comply with AS/NZS 4024 safety standards and are built using quality industrial components for reliability and longevity.

The ROI and Long-Term Value of Robotic Case Packing

Labour Savings and Multi-Shift Operation Advantages

Automating case packing typically results in a return on investment within 12–24 months. In multi-shift environments, payback can be even faster thanks to reduced labour hours and consistent production output.

Predictable Performance and Reduced Maintenance Costs

Robotic systems deliver predictable performance with lower ongoing maintenance costs compared with traditional mechanical machines. Routine service intervals are straightforward, keeping your system operating at peak efficiency.

Real-World ROI Timelines for Australian Manufacturers

Process Evolution has helped clients achieve full payback in as little as one year, depending on throughput and shift coverage. The long-term savings — in labour, safety, and reliability — continue for the lifetime of the system.

Conclusion: Flexible Automation for a Smarter, Scalable Future

Robotic Case Packing is redefining what’s possible in end-of-line automation. With unmatched flexibility, scalability, and reliability, it allows manufacturers to manage multi-SKU operations efficiently while reducing costs and improving safety.

At Process Evolution, we combine 27 years of automation expertise with local design, manufacturing, and support to deliver systems built for Australian industry. Whether you’re seeking to improve throughput, handle more SKUs, or prepare for future growth, our Robotic Case Packing solutions are engineered to evolve with your business.

Contact Process Evolution today to discover how robotic automation can transform your case-packing operations and future-proof your production line.