Future-Proofing Your Line with Robotic Palletising

Why Future-Proofing Matters in Modern Manufacturing

Adapting to Labour Shortages and Rising Costs

Australia’s manufacturing sector is under pressure. Skilled labour is increasingly hard to find, wages continue to rise, and expectations around safety and efficiency are growing. For manufacturers who still rely on manual palletising, these challenges quickly translate into higher costs and lower productivity.

Future-proofing your line means taking steps today that will protect your competitiveness tomorrow. Automation—particularly Robotic Palletising—offers one of the most practical, high-impact ways to do that.

Preparing for Changing Product Demands and Shorter Runs

Consumer habits are changing rapidly, driving shorter production runs and greater SKU diversity. Manufacturers that can’t adapt risk being left behind. Palletising systems need to handle mixed products, frequent changeovers, and dynamic order volumes.

That’s where palletising automation comes in—it brings agility, consistency, and control to the end of the line.

The Role of Robotic Palletising in Building Flexible Production

How Palletising Automation Enhances Efficiency and Reliability

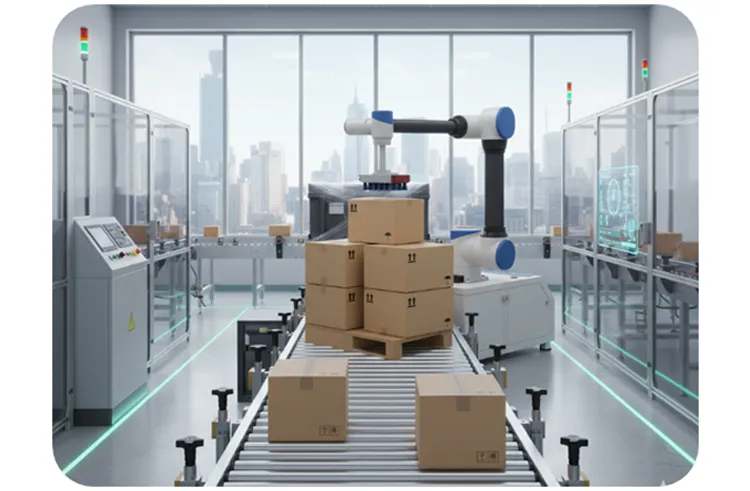

Unlike manual operations, robotic palletisers perform the same precise movements thousands of times per day without fatigue or inconsistency. They optimise stacking patterns, eliminate lifting injuries, and ensure every pallet is perfectly built.

When connected to your production network, a robotic palletiser provides reliable, measurable efficiency that can be monitored and improved continuously.

Scalable Systems That Grow with Your Business

A future-proofed system is one that can evolve. Process Evolution’s robotic palletising solutions are modular—meaning new stations, grippers, or pallet positions can be added as production grows. Whether starting with a single pallet station or integrating with case-pack, labelling, and wrapping, scalability ensures long-term value from your investment.

Key Technologies Powering the Next Generation of Palletising

From Traditional Robots to Advanced Robotic Palletisers

Traditional industrial robots have long dominated palletising for high-volume lines, but recent advancements in servo control, software, and sensing have transformed what’s possible. Modern automated palletising systems can handle varied product shapes, weights, and patterns—reducing setup time and improving output.

The Rise of Cobot Palletising and Hybrid Automation

Collaborative robots, or cobots, are now entering the palletising space in force. They combine safety and simplicity with impressive performance, making them ideal for small-to-medium manufacturers or sites with limited space.

Our Cobot Palletiser range offers intuitive interfaces, rapid recipe changes, and a compact footprint—bridging the gap between manual handling and full industrial automation.

Smart Features – Vision, Sensors, and Data Connectivity

Future-ready systems use sensors, cameras, and data analytics to optimise operation. Vision-guided palletisers detect carton orientation, barcode information, and stacking quality in real time. These capabilities enable predictive maintenance, reduced downtime, and seamless integration with warehouse or ERP systems.

How Robotic Palletising Future-Proofs Your Production Line

Minimising Downtime and Manual Intervention

Automated palletisers run continuously with minimal human input. Changeovers can be automated through stored recipes, allowing quick transitions between products. This not only keeps output consistent but also protects against production disruption from staff shortages or turnover.

Meeting New Safety and Compliance Standards

Workplace health and safety is a major cost driver for manufacturers. Robotic palletising dramatically reduces repetitive strain injuries, lifting incidents, and fatigue. All Process Evolution systems are designed in accordance with AS/NZS 4024 safety standards, ensuring compliance and peace of mind.

Rapid Changeovers for Multi-SKU and Seasonal Production

Whether you’re running contract manufacturing lines, packaging seasonal products, or handling various bottle or carton sizes, robotic palletisers adapt easily. Quick-release tooling, recipe-based setup, and vision-based product recognition make flexibility effortless.

Choosing the Right Automated Palletising System

Bespoke Industrial Palletising Cells for High Throughput

For manufacturers with stable, high-volume production lines, custom-engineered industrial robotic cells offer maximum performance. These can include pallet dispensers, automatic wrapping, and integrated labelling—delivering end-to-end palletising automation.

Compact and Flexible Cobot Palletisers

Cobot palletisers excel in environments where space, variety, and flexibility are key. They’re easy to redeploy, require minimal guarding, and can be programmed in minutes. Ideal for sites upgrading from manual stacking to automation for the first time.

Dedicated Palletising Machines Like the AWP Model

Our AWP palletising system offers the strength of an industrial robot and the simplicity of a cobot. With servo-driven axes, high payload capacity, and standardised layout options, it’s a practical, future-ready palletising platform designed for Australian manufacturers.

Why Partner with an Australian Automation Specialist

Designed and Supported Locally for Maximum Uptime

At Process Evolution, we don’t just import automation—we design, integrate, and support robotic palletising systems right here in Australia. That means fast response times, custom engineering, and local service teams that understand your production environment.

Expertise Across Robotics, Integration, and Safety Standards

Our engineers bring decades of experience in robotics, control systems, and manufacturing integration. Every project is delivered to meet your site’s workflow, product handling, and compliance needs from concept to commissioning.

Long-Term Service, Training, and Spare Parts Support

With local support, you’re never left waiting for overseas assistance. We provide comprehensive training, preventive maintenance, and readily available spare parts to ensure long-term reliability and the best possible ROI.

The Long-Term Payoff of Robotic Palletising

Lower Cost per Pallet Over Time

The capital investment in automation quickly pays for itself through lower labour costs, reduced downtime, and improved efficiency. Once installed, the ongoing cost per pallet drops dramatically compared to manual handling.

Improved Productivity and Employee Retention

By removing repetitive, physically demanding work, manufacturers can re-deploy staff into more rewarding, skilled roles. The result is higher productivity, better job satisfaction, and lower turnover.

Building a Smarter, More Competitive Operation

Robotic Palletising isn’t just about automation—it’s about building resilience. Manufacturers who invest now gain the flexibility to respond faster to demand changes, compliance requirements, and market shifts, ensuring long-term competitiveness.

Conclusion: Future-Proof Your Line Today

In a world of constant change, Robotic Palletising is one of the most effective ways to future-proof your production line. From labour challenges to growing SKU complexity, the benefits are clear: consistency, safety, and scalability.

Process Evolution helps Australian manufacturers take the next step in automation with locally supported systems designed for lasting performance.

Explore how we can help you build a smarter, more efficient, and future-ready production line.