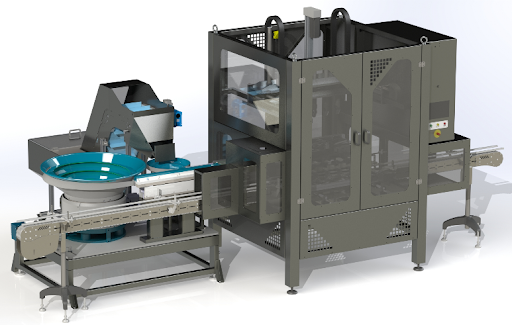

Flexible Capping Machines for Contract Manufacturers

In the fast-paced world of contract manufacturing, flexibility and efficiency are paramount. Manufacturers filling products into a diverse range of bottle and closure formats need equipment that can keep up with ever-changing demands. Our flexible capping machines are designed to meet these challenges head-on, offering unmatched adaptability and performance. Learn why our solution is one of the most innovative and efficient on the market.

Why Choose Flexible Capping Machines for Your Manufacturing Needs?

Meeting the Challenges of Diverse Bottle and Closure Formats

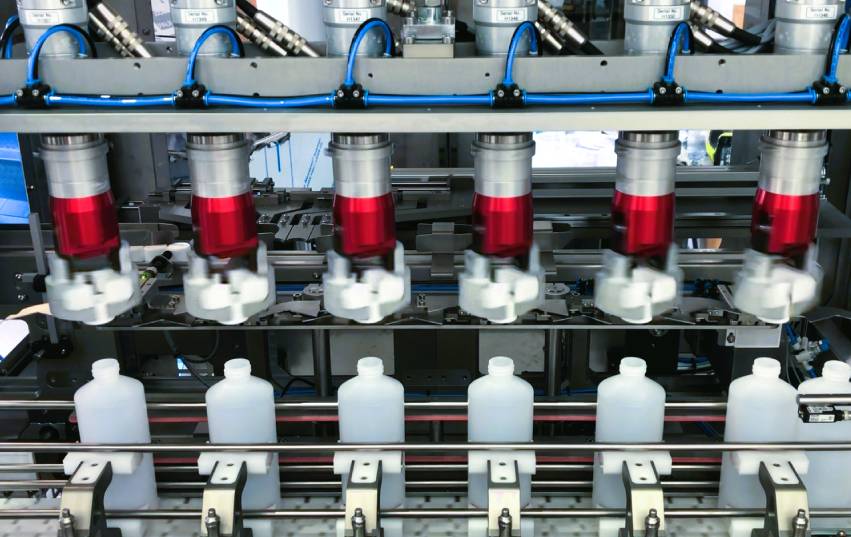

Contract manufacturers often deal with a wide array of bottles and closures, from standard screw-on caps to specialised flip tops, press-on caps, and pumps with dip tubes. Switching between these formats can be time-consuming and prone to errors without the right equipment. Our flexible capping machines seamlessly adapt to these diverse requirements, ensuring accurate and efficient capping every time.

Fully Programmable for Effortless Recipe Management

Efficiency isn’t just about speed; it’s about simplicity. Our capping machines feature fully programmable settings that store multiple recipes. Operators can quickly recall specific configurations at the touch of a button, reducing setup times and minimising the risk of errors. This feature is particularly valuable for manufacturers handling frequent product changeovers.

Key Features of Our Flexible Capping Machines

Cost-Effective Tooling for Multiple Product Lines

Manufacturers often hesitate to invest in advanced equipment due to the high cost of tooling. Our flexible capping machines address this concern with cost-effective tooling designed for longevity and ease of use. Whether you’re running small batches or high-volume production, the tooling is built to optimise your operational costs.

Quick and Easy Tooling Changes for Maximum Efficiency

Time is money in contract manufacturing. Our capping machines are engineered for quick and easy tooling changes, significantly reducing downtime during product changeovers. The intuitive design ensures that your team can switch between formats swiftly, keeping production lines running smoothly.

Versatility in Capping Options: Screw Caps, Flip Tops, Press-Ons, and Pumps

From screw caps and flip tops to press-on caps and pumps with dip tubes, our machines can handle it all. This versatility ensures that you can accommodate a wide range of client needs without requiring multiple pieces of specialised equipment. The flexibility of our capping machines makes them an invaluable asset for contract manufacturers.

How Flexible Capping Machines Benefit Contract Manufacturers

Reducing Downtime with Seamless Recipe Recall

Production downtime is a significant concern for any manufacturer. Our flexible capping machines minimise this issue with their programmable recipe recall functionality. By storing all your configurations, these machines enable you to switch between products with minimal disruption, keeping your operations on schedule.

Supporting Diverse Product Ranges with Ease

As consumer preferences evolve, so do the demands placed on contract manufacturers. Our capping machines are designed to handle diverse product ranges, making it easier for your business to stay competitive and meet customer expectations.

Why Our Flexible Capping Solution Stands Out

Designed Specifically for Contract Manufacturers

Our flexible capping machines are purpose-built to address the unique challenges faced by contract manufacturers. From their programmable features to their adaptability, every aspect of these machines is tailored to enhance productivity and reduce operational complexity.

One of the Most Flexible Capping Solutions on the Market

Few capping machines offer the level of flexibility that ours do. By combining advanced technology with user-friendly design, we’ve created a solution that stands out in the industry. Whether you’re a small-scale operation or a large contract manufacturer, our machines are equipped to meet your needs.

Future-Proof Your Manufacturing Process with Flexible Capping Machines

Adapting to Changing Market Demands

The manufacturing landscape is constantly evolving. With our flexible capping machines, you can future-proof your operations to adapt to new market demands. Their versatility ensures that you’ll be ready to take on new product lines and customer requirements with ease.

Enhancing Automation and Reducing Operational Costs

Automation is key to reducing labour costs and improving efficiency. Our capping machines integrate seamlessly into automated production lines, streamlining your processes and delivering long-term savings. By investing in our flexible solution, you’re investing in a more efficient and cost-effective future.

Learn More About Flexible Capping Machines

At Process Evolution, we’re committed to helping contract manufacturers achieve their goals. Our flexible capping machines are designed to deliver unmatched performance and adaptability. Contact us today to learn more about how we can provide a bespoke solution tailored to your specific needs.

With Process Evolution’s flexible capping machines, you can enhance your production capabilities and stay ahead of the competition. Let us help you revolutionise your manufacturing process.