Flexible Capping Machines for Multi-SKU Lines

The Growing Need for Flexibility in Modern Manufacturing

Multi-SKU Production and Constant Changeovers

In today’s manufacturing landscape, product variety is no longer an exception — it’s the standard. Many contract manufacturers and brand owners in Australia manage dozens, even hundreds, of SKUs across multiple bottle sizes and closure types. Each product variation adds complexity to the production line, especially during changeovers.

Flexible Capping Machines are essential to keep pace with this demand. Unlike traditional systems designed for single products, modern cappers adapt easily to different bottle and cap combinations, helping manufacturers maintain productivity and quality across all SKUs.

The Challenge of Managing Different Caps and Bottles

From flip-top and screw caps to pumps, sprayers, and press-on closures — each cap behaves differently. Managing these variations manually introduces downtime, inconsistency, and operator fatigue. Flexible automation removes these challenges by providing fast, repeatable setup changes without mechanical adjustments.

Why Flexibility Has Become a Competitive Advantage

As batch sizes shrink and product diversity expands, flexibility isn’t just a feature — it’s a strategic advantage. Manufacturers with adaptable, easy-to-configure Capping Machines can meet changing customer demands faster, minimise downtime, and maintain consistent output without costly retooling.

What Are Capping Machines and How Do They Work?

The Role of Capping Machines in Bottle Packaging Lines

A Capping Machine applies and tightens caps onto bottles and containers with consistent torque and positioning. It’s a critical part of any packaging line — ensuring product integrity, preventing leaks, and preserving shelf life.

Whether the product is shampoo, lotion, detergent, or liquid supplements, automated capping ensures every container leaves the line sealed, uniform, and ready for distribution.

Types of Capping Systems – Screw, Snap, and Pump

There are multiple types of Capping Machines, each tailored to specific packaging needs:

• Screw cappers for threaded caps that require torque control.

• Snap cappers for press-on or push-fit closures.

• Pump and trigger cappers for irregular closures found in personal care and cleaning products.

At Process Evolution, we design flexible systems that handle multiple closure types on one machine — removing the need for separate equipment for each cap format.

From Manual Equipment to Fully Automated Capping Machines

Manual and semi-automatic machines may suit small operations, but as volumes increase, the inefficiency becomes evident. Fully automated Capping Machines streamline production, improve repeatability, and reduce labour costs — a key step in scaling sustainably.

Why Flexible Capping Machines Are Ideal for Multi-SKU Lines

Tool-Free Adjustments and Fast Changeovers

Traditional cappers require manual adjustments, which are slow and prone to error. Flexible systems use servo-driven actuators and recipe-based settings to perform changeovers in minutes — with no tools or manual intervention required.

This is especially valuable for multi-SKU lines, where frequent product changes can otherwise lead to excessive downtime.

Handling Multiple Cap Types with a Single Machine

Flexible Capping Machines can accommodate screw caps, pumps, flip caps, and more using interchangeable grippers or adaptive torque heads. This multi-capability design supports a wide range of packaging without compromising on accuracy or performance.

Precision Torque Control for Quality and Consistency

Consistent torque is crucial for product quality and compliance. Automated torque monitoring ensures each cap is tightened to specification, reducing rejects and ensuring every product meets brand standards.

Key Design Features of Modern Capping Machines

Servo-Driven Control for Accuracy and Repeatability

Servo motors allow precise motion control for torque, height, and speed — ensuring perfect cap placement every time. This not only improves consistency but also reduces wear and maintenance.

Recipe-Based Setup for Quick Product Switchovers

Operators can load saved recipes directly from an HMI touchscreen, instantly adjusting parameters for different bottles or closures. This intuitive interface eliminates guesswork, speeding up production and simplifying training.

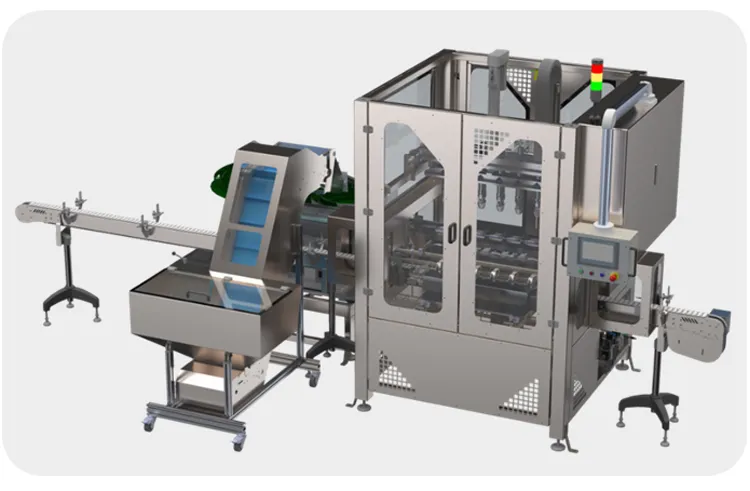

Integration with Filling, Labelling, and Case Packing Systems

Capping Machines can be integrated with other automation modules — including bottle filling, labelling, and case packing — for a seamless end-of-line solution. Process Evolution designs and builds complete packaging systems that improve throughput while maintaining flexibility.

The Benefits of Investing in Flexible Capping Automation

Higher Efficiency and Reduced Downtime

Automation removes the stop-start inefficiency of manual operations. With servo-driven control and quick-change functionality, flexible cappers maintain consistent output — even across high SKU counts.

Labour Savings and Improved Safety

By automating repetitive and ergonomically demanding tasks, Capping Machines free up staff for higher-value work while improving operator safety and reducing fatigue-related errors.

Better Product Quality and Fewer Rejects

Accurate, consistent torque control ensures that every bottle is sealed correctly — eliminating under- or over-tightening issues that can lead to leaks, product loss, or consumer complaints.

Supporting Multi-SKU Operations with Smart Technology

Digital Recipe Management and Line Traceability

Smart software allows recipe storage, batch tracking, and digital logging of torque data. This makes traceability easier for quality audits and compliance, particularly in regulated industries.

Real-Time Monitoring and Data Integration

Connecting capping equipment to plant monitoring systems provides live performance insights — from torque verification to production counts — helping identify and resolve inefficiencies quickly.

How Smart Controls Reduce Operator Error

Modern Capping Machines guide operators through automated setup procedures and lock out incorrect configurations, dramatically reducing the risk of human error.

Why Work with a Local Australian Automation Partner

Locally Designed and Built for Australian Conditions

At Process Evolution, our Capping Machines are designed, built, and supported in Australia. We understand the needs of Australian manufacturers — from compliance and safety standards to environmental conditions — and build equipment that lasts.

Local Support, Training, and Spare Parts Availability

Working with a local partner means faster response times, local spare parts availability, and on-site support when you need it most. Our experienced team provides full lifecycle service — from design to installation and ongoing optimisation.

Proven Expertise in Contract Manufacturing Environments

With decades of experience designing automation systems for contract manufacturing and multi-SKU operations, we deliver proven solutions that combine flexibility, speed, and reliability.

The ROI and Scalability of Flexible Capping Systems

Adapting to Growth and New Product Launches

Our modular systems are designed to evolve with your business. Add heads, adjust control parameters, or integrate additional modules as production needs expand — all without replacing your existing system.

Short Payback Periods through Labour and Time Savings

Most customers experience a return on investment within 12–24 months, thanks to improved throughput, reduced labour, and higher efficiency.

Long-Term Value from Locally Supported Equipment

With robust construction, quality components, and responsive local support, Process Evolution’s Capping Machines provide years of reliable service and outstanding long-term value.

Conclusion: Future-Proof Your Line with Flexible Capping Automation

The rise of multi-SKU manufacturing demands flexibility, consistency, and smart automation. Investing in Flexible Capping Machines allows manufacturers to handle diverse product ranges efficiently while reducing downtime and labour costs.

At Process Evolution, we design and build flexible capping systems that grow with your business — offering Australian-built quality, proven reliability, and local expertise.

Contact Process Evolution today to learn how our Capping Machines can help you improve flexibility, scalability, and long-term production performance.