Flexible Capping Machines by Process Evolution

In today’s fast-paced manufacturing environment, flexibility and efficiency are paramount. Process Evolution understands the needs of contract manufacturers who deal with a diverse range of bottle and closure formats. Our capping machines are designed to provide the ultimate capping flexibility, ensuring you can handle any capping task with ease and precision. In this blog, we will explore the evolution of capping machines, the importance of flexibility, and the unique features and advantages of Process Evolution’s capping machines.

The Evolution of Capping Machines

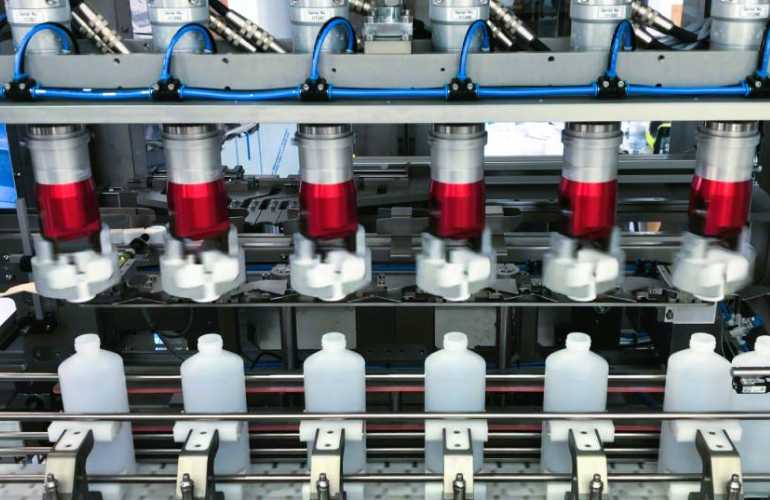

Capping machines have come a long way from their humble beginnings. Initially, manual capping was the norm, which was labour-intensive and prone to inconsistencies and workplace injuries. With the advent of automation, capping machines became more sophisticated, offering increased speed and accuracy. Today, capping machines like those from Process Evolution incorporate advanced technology to deliver unparalleled flexibility and efficiency. Most modern machines, however, are tailored to only a small range of product variation and are mostly suited towards large volume production runs i.e. they are set-up to run the same product continuously. Process Evolution’s capping machines are a game-changer for contract manufacturers dealing with diverse product ranges. Our flexible capping machines are designed to meet these needs, offering unparalleled versatility and reliability making them indispensable in the contract manufacturing industry.

What Are Capping Machines?

Capping machines are essential pieces of equipment in the packaging industry. They are used to securely seal bottles and containers with various types of caps, including screw-on caps, flip-top caps, press-on caps, and pumps and sprays with dip tubes. By automating the capping process, these machines ensure consistent, reliable seals that protect product integrity and extend shelf life. Process Evolution’s capping machines are designed to meet the diverse needs of contract manufacturers, providing the flexibility to handle different products and packaging requirements.

The Importance of Flexibility in Capping Machines

Flexibility is a crucial factor for contract manufacturers who need to switch between different products and packaging formats frequently. Process Evolution’s capping machines are built with this flexibility in mind. They allow for quick and easy changes between different cap types and bottle sizes, reducing downtime and increasing productivity. This flexibility ensures that manufacturers can meet the varying demands of their clients without compromising on quality or efficiency.

Features of Process Evolution’s Capping Machines

Fully Programmable Systems

One of the standout features of Process Evolution’s capping machines is their fully programmable systems. These machines can store multiple recipes, allowing operators to switch between different capping setups at the touch of a button. This programmability not only saves time but also ensures consistent results, making it easier to maintain high-quality standards across different production runs.

Cost-Effective, Quick & Easy Tooling Changes

Our capping machines are designed to be cost-effective, with tooling changes that are quick and easy to perform. This feature is particularly beneficial for contract manufacturers who need to adapt to different products frequently. By minimising the time and effort required for tooling changes, our machines help reduce production costs and improve overall efficiency.

Versatile Cap Compatibility

Process Evolution’s capping machines are capable of handling a wide range of cap types, including screw-on caps, flip-top caps, press-on caps, and pumps and sprays with dip tubes. This versatility ensures that manufacturers can use a single machine for various products, reducing the need for multiple pieces of equipment and streamlining the production process.

Advantages of Using Process Evolution’s Capping Machines

Enhanced Efficiency

Our capping machines are designed to enhance efficiency in the manufacturing process. By automating the capping process and allowing for quick changes between different setups, our machines help increase production speed and reduce downtime. This improved efficiency translates to higher output and lower operational costs.

Recipe Storage and Retrieval

The ability to store and retrieve multiple capping recipes is a significant advantage of our machines. This feature ensures that manufacturers can quickly switch between different products without the need for extensive reconfiguration. It also helps maintain consistent quality, as the stored recipes can be precisely replicated for each production run.

Handling Diverse Bottle and Closure Formats

Process Evolution’s capping machines are capable of handling a wide range of bottle and closure formats. This versatility is crucial for contract manufacturers who work with various products and packaging requirements. Our machines can easily adapt to different sizes and shapes, ensuring a secure and reliable seal for every product.

Why Choose Process Evolution’s Capping Machines?

Developed for Contract Manufacturers

Our capping machines are specifically developed with contract manufacturers in mind. We understand the challenges of dealing with diverse products and packaging formats, and our machines are designed to provide the flexibility and efficiency needed to meet these challenges. With Process Evolution, you can be confident that you are investing in equipment that will support your business’s growth and success.

Commitment to Quality and Innovation

At Process Evolution, we are committed to delivering high-quality, innovative solutions to our clients. Our capping machines are built to the highest standards, incorporating the latest technology to ensure optimal performance. By choosing our machines, you are choosing a partner dedicated to helping you achieve excellence in your manufacturing operations.

Conclusion: The Future of Capping Machines with Process Evolution

As the manufacturing industry continues to evolve, the need for flexible, efficient capping solutions will only grow. Process Evolution is at the forefront of this evolution, providing capping machines that meet the diverse needs of contract manufacturers. With our fully programmable systems, cost-effective tooling changes, and versatile cap compatibility, our capping machines offer the ultimate flexibility and efficiency. Trust Process Evolution to be your partner in achieving manufacturing excellence and staying ahead of the competition.